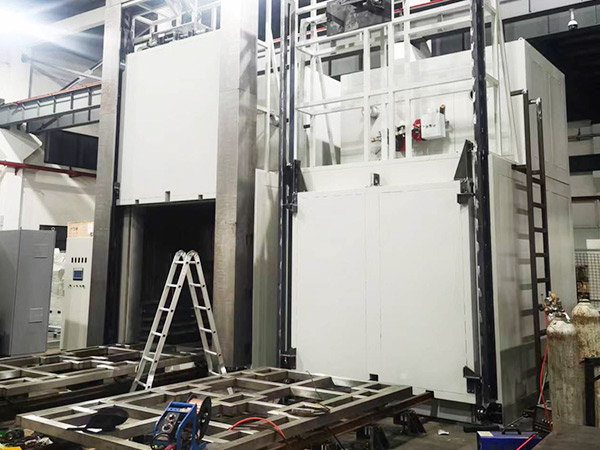

An industrial truck loading oven, also known as a batch oven or walk-in oven, is designed for heavy industrial workpieces, suitable for composite curing, chemical product drying, foundry mold drying, etc., with a temperature range from ambient to 600℃.<br /> The truck-loading structure is ideal for batch processing of large castings, molds, and steel components, with a maximum load capacity of 20 tons.<br /> Optional explosion-proof and exhaust gas treatment configurations are available for special industries like chemical and coating.

Electric Door System: Optional electric or manual door for easy operation.

Multi-layer Shelves: Stainless steel shelves with high load capacity.

Safety Features: Emergency stop button, door interlock, and alarm system.

Customization: Non-standard sizes, special temperature ranges (up to 600℃), and materials (e.g., stainless steel inner liner).

| Chamber size | Temperature Range | Weight | Voltage | Power | Temp controlaccuracy |

| Custom Size | max temperature 600℃ | 5~20 tons | 220/380 | Custom Power | ±1℃~±2℃ |

GUANDN will design equipment based on your production volume, temperature needs (30–2200°C), automation requirements, footprint needs, and more.

From the initial design concept, production, to after - sales service, Our team of experienced engineers, with over 15 years of design experience on average, will work closely with you to provide CAD design, 3D layout, and max temp thermal simulation.

Share your specs—we’ll design, optimize, and deliver.

Address:No. 998, Juting Road, Zhuangxing Town, Fengxian District, Shanghai, China

Email:support@gdoven.com

Phone:+86 19921692198

WhatsApp:+86 19921692198

Share your specs—we’ll design, optimize, and deliver.

Address:No. 998, Juting Road, Zhuangxing Town, Fengxian District, Shanghai, China

Email:support@gdoven.com

Phone:+86 19921692198

WhatsApp:+86 19921692198